Adhesive Tapes Applica

DENSEMATE is dedicated to continuously refining production processes and upgrading management systems, ensuring that every client is delivered with top-tier product quality and premium service. What’s more, we boast robust expertise in crafting tailored, optimal solutions to meet the diverse needs of industries across the board.

Pivotal Role of Adhesive Tapes Across Industries

- Automotive

- Electric &Electronics

- Appliance & Housing

- Construction

- Renewable Energy

- Packaging & Printing

- Textile & Apparel

- Other Industries

Our Premium Adhesive Product Range

Our company provides high-quality adhesive products and tailored system solutions for various industries. These solutions help our partners streamline production workflows, enhance product performance, and effectively control operational costs.

High Temperature Resistant Tapes

Industrial Foam Tapes

Dual-Sided Adhesive Tapes

Thermal Conductive Tapes

Masking Tapes & Films

Genuine 3M Adhesive Tapes

High-Strength VHB Tapes

Precision Die Cutting Gaskets

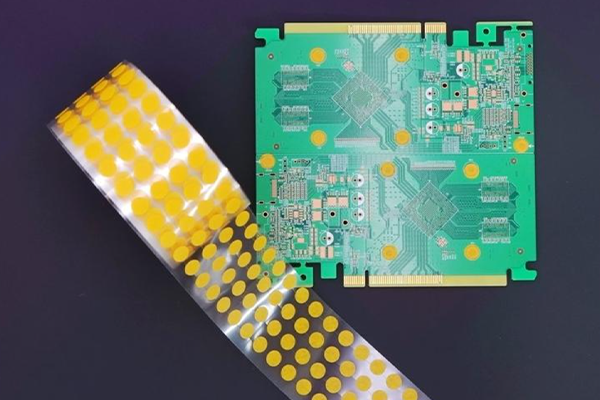

Adhesive Solutions for Electronics & Telecom

Beyond basic bonding and insulation, our adhesive tapes deliver specialized performance for electronics manufacturing—including EMI/RFI interference shielding and efficient thermal dissipation to maintain device stability.

High-Temp Polyimide Tapes

Metalized Shielding Tapes

ESD Protective Adhesive Tapes

High-Dielectric Insulation Tapes

EMI/RFI Shielding Tapes

Precision Surface Masking Tapes

Thermal Dissipation Tapes

Structural VHB Bonding Tapes

Electrical Adhesive Solutions for Residential & Commercial Use

We provide tailored adhesive products for electrical scenarios—covering panel installation, secure product transit, foam processing, component labeling, surface protection, and other specialized application needs.

High-Temp Polyimide Films

Reusable Nano Adhesive Tapes

PET Silicone Release Tapes

Heavy-Duty Electrical Duct Tapes

Precision Surface Masking Tapes

Heat-Resistant Aluminum Foil Tapes

Dual-Sided Bonding Tapes

Custom Die-Cut Adhesive Tapes

Construction-Grade Adhesive Solutions

Our construction adhesive products support sealing, bonding, insulation, masking and surface protection—helping deliver buildings that are long-lasting, aesthetically polished, and energy-conserving.

Weather-Resistant Foam Tapes

Heat-Seal Aluminum Foil Tapes

Heavy-Duty Dual-Sided Tapes

Multi-Purpose Construction Duct Tapes

Surface-Friendly Paper Masking Tapes

Watertight Butyl Sealing Tapes

High-Strength 3M VHB Tapes

Scratch-Resistant Protective Films

Adhesive Solutions for Renewable Energy Systems

Our adhesive products deliver reliable support for renewable energy equipment—covering bonding, assembly, protection, sealing and thermal control needs for solar panels, wind turbines and other clean energy installations.

High-Temp Polyimide Films

Weather-Resistant Silicone Tapes

Durable Acrylic Foam Tapes

Solar Panel Surface Protection Tapes

Watertight Butyl Rubber Tapes

Efficient Thermal Conductive Tapes

Heat-Seal Aluminum Foil Tapes

High-Strength VHB Mounting Tapes

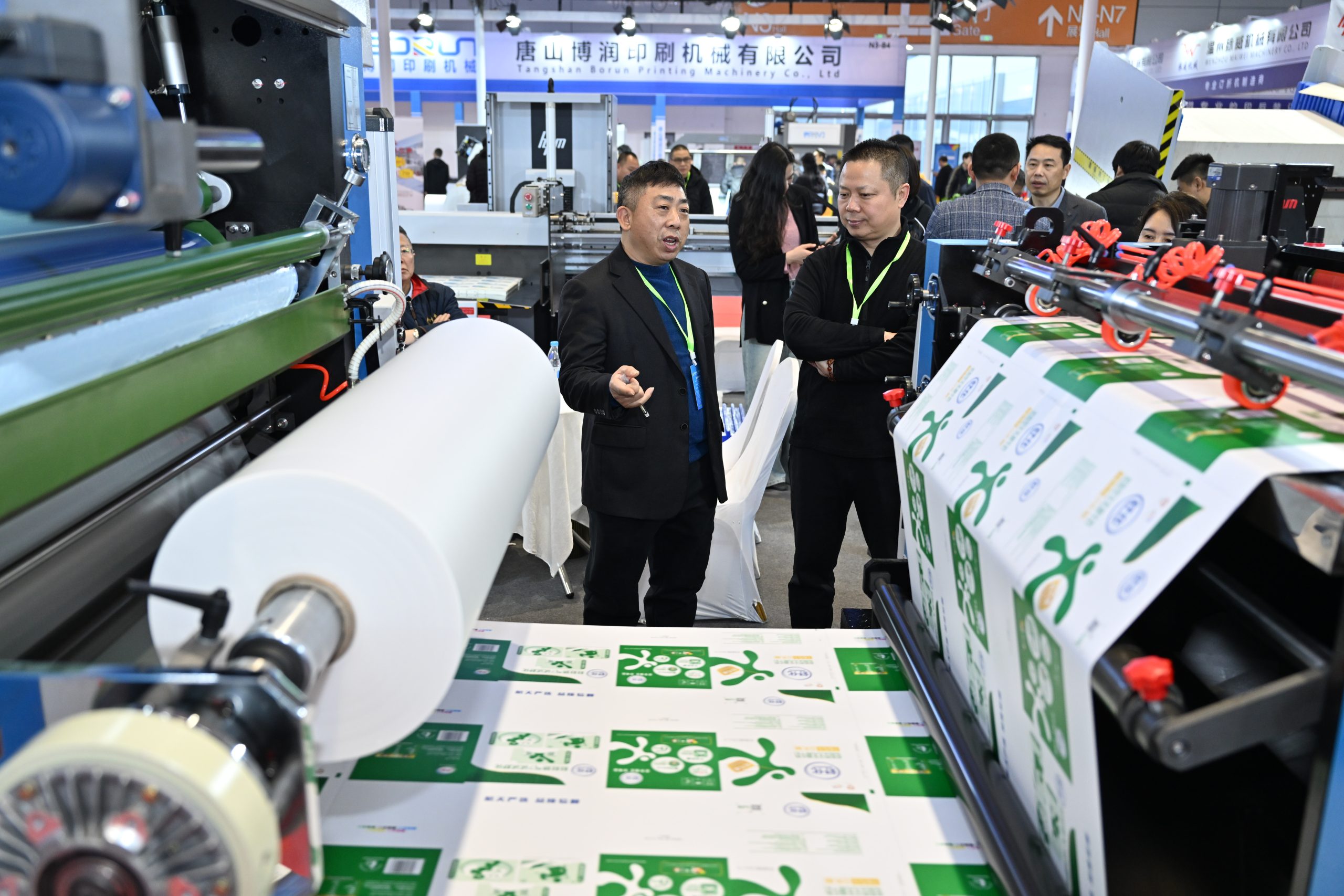

Printing Industry Adhesive & Auxiliary Tape Solutions

We provide laminating tapes (foam, film, cloth-based) tailored to diverse printing processes, plus auxiliary tapes that optimize workflows—covering guide roll wrapping, plate edge sealing, winding, and defect marking.

Printing-Specific Dual-Sided Tapes

Surface-Protective Paper Masking Tape

Durable Kraft Paper Laminating Tape

BOPP-Based Printing Auxiliary Tape

High-Temp Resistant Printing Tapes

Workflow-Optimized Warning Tapes

Precision Die-Cut Printing Gaskets

Adhesive Solutions for Textile & Apparel Manufacturing

The textile and apparel production process relies on diverse adhesive tapes—backed by our industry expertise and advanced technology, we deliver tailored adhesive solutions to meet the unique needs of this sector.

Fabric-Friendly Dual-Sided Tapes

Textile Surface Masking Tapes

Apparel-Safe Conductive Tapes

Garment Reflective Adhesive Tapes

Flame-Retardant Textile Tapes

Garment Hook & Loop Fastener Tapes

Non-Woven Fabric Bonding Tapes

Custom Die-Cut Apparel Tapes

Cross-Industry Adhesive Products & System Solutions

We deliver tailored self-adhesive products and integrated solutions across industries—helping clients streamline production workflows, enhance product reliability, and achieve cost efficiency.

Extreme-Temperature Resistant Tapes

Industrial-Grade Foam Bonding Tapes

High-Strength Dual-Sided Tapes

Efficient Thermal Management Tapes

Precision Masking Tapes & Films

Genuine 3M Adhesive Solutions

Structural VHB Bonding Tapes

Custom Die-Cut Sealing Gaskets

Advantages of Adhesive Tapes in Various Industries

Key Advantages of Modern Adhesive Tapes

Highly Adaptive Design

Adhesive tapes can be customized by size, thickness, bonding strength, and material to fit diverse scenarios—whether for bonding, sealing, insulation, masking, or labeling, there’s a tailored tape for every task.

Simplified Application

Unlike traditional bonding methods, adhesive tapes can be applied quickly without special tools or skills. This accelerates production and assembly workflows, directly boosting operational efficiency.

Sleek Visual Finish

Adhesive tapes create clean, seamless surfaces. For example, in automotive manufacturing, replacing mechanical fasteners with tapes results in smoother vehicle exteriors and neater design lines.

Cost-Effective Solutions

Adhesive tapes cut overall production costs by eliminating the need for drilling, welding, or extra fasteners—processes that typically consume significant time and resources.

Long-Term Durability

Modern adhesive tapes are engineered to resist UV radiation, temperature changes, moisture, and chemicals. This makes them reliable for long-duration applications in harsh environments.

Enhanced Safety & Health

Adhesive tapes reduce exposure to glue solvents and eliminate welding-related risks. They also support safer product design—such as non-slip tapes used in industrial workspaces.

Beyond these benefits, adhesive tapes also offer functional diversity, sustainability, and innovative design—making them a top choice for industries worldwide. Their adaptability ensures they stay at the forefront of industrial innovation.

Key Advantages of Modern Adhesive Tapes

Highly Adaptive Design

Adhesive tapes can be customized by size, thickness, bonding strength, and material to fit diverse scenarios—whether for bonding, sealing, insulation, masking, or labeling, there’s a tailored tape for every task.

Simplified Application

Unlike traditional bonding methods, adhesive tapes can be applied quickly without special tools or skills. This accelerates production and assembly workflows, directly boosting operational efficiency.

Sleek Visual Finish

Adhesive tapes create clean, seamless surfaces. For example, in automotive manufacturing, replacing mechanical fasteners with tapes results in smoother vehicle exteriors and neater design lines.

Cost-Effective Solutions

Adhesive tapes cut overall production costs by eliminating the need for drilling, welding, or extra fasteners—processes that typically consume significant time and resources.

Long-Term Durability

Modern adhesive tapes are engineered to resist UV radiation, temperature changes, moisture, and chemicals. This makes them reliable for long-duration applications in harsh environments.

Enhanced Safety & Health

Adhesive tapes reduce exposure to glue solvents and eliminate welding-related risks. They also support safer product design—such as non-slip tapes used in industrial workspaces.

Beyond these benefits, adhesive tapes also offer functional diversity, sustainability, and innovative design—making them a top choice for industries worldwide. Their adaptability ensures they stay at the forefront of industrial innovation.

REQUEST A QUOTE

INFORMATION NEEDED FOR QUOTATION REQUEST

To ensure we deliver a precise and prompt quotation tailored to your needs, please share the following detailed information when submitting your inquiry:

Adhesive Tape Specifications

Please specify key parameters including width, thickness, length, anticipated order volume, and any custom requirements (e.g., material type, adhesion strength).

Application & Industry Details

Indicate the specific industry or end-use scenario for the tape (e.g., automotive assembly, electronics manufacturing). This helps us recommend the optimal product solution.

Die-Cut Component Requirements

For die-cut parts, provide exact dimensions, base material specifications, and detailed technical drawings. Drawings can be emailed to sale@densemate.com for review.

We appreciate your interest in our industrial adhesive tape solutions and look forward to providing you with a competitive and accurate quotation.